What is Hopper?

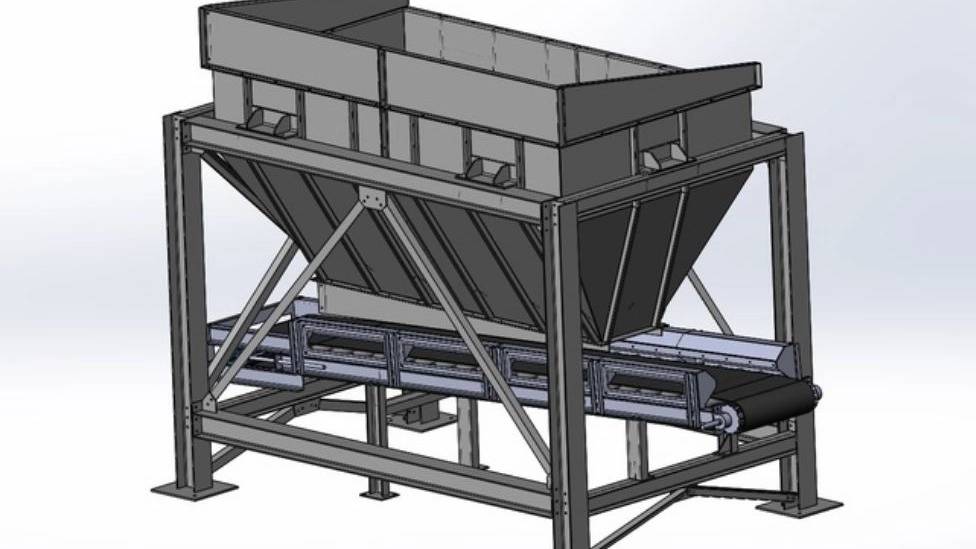

Hopper is a large industrial hopper which is considered as a storage equipment in industries. The application of industrial hopper is warehouse and material storage and preparation for transfer to the production line. This device can be made from one tank or as a multi-tank weighing system. At the end of the tanks, there are material transfer lines such as conveyors or conveyors. The shape of the hopper is like a funnel or a pyramid, which is used to create a permanent and continuous flow of materials in production processes.

Hopper types according to the components of the constituent

Belt hopper: It consists of several hoppers or hoppers for storing materials and a conveyor belt under the hopper. When the conveyor starts working, the material is removed from the hopper. The speed of the conveyor belt can be adjusted by the inverter. Band hopper is used for materials with moisture such as mud. Mardone hopper: If a rotating mardone is used under the hopper, it is called a mardone hopper. This type of funnel is suitable for hot or flowing materials such as sand. Vibrating hopper: In the vibrating hopper, there is a vibrating table under the hopper, which vibrates and causes the material to move and fall out of the hopper. This type of hopper is suitable for gravel and dry materials.

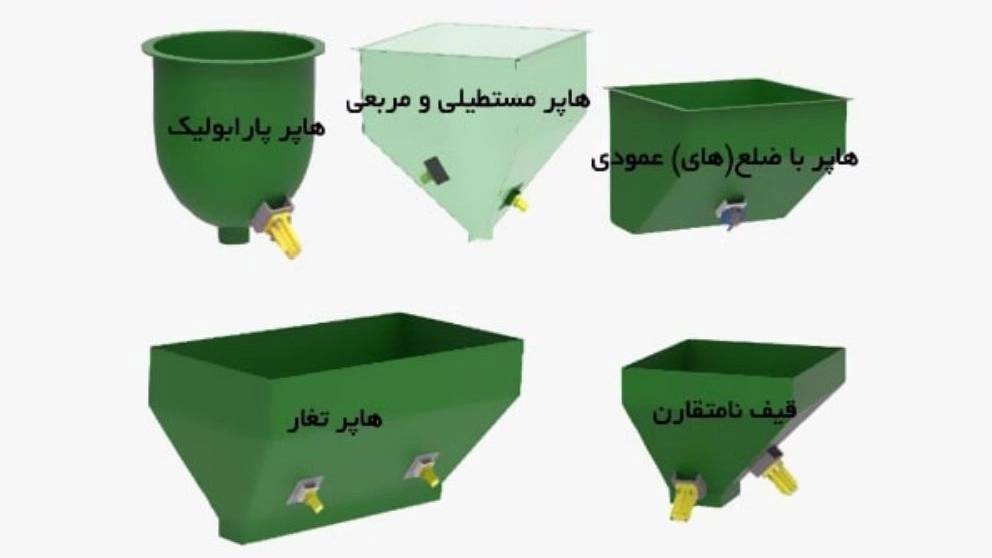

Hopper types based on geometric design

It is produced in variable dimensions according to wide application. The geometrical design is based on the user's needs. The shape of the cross-section, dimensions, mechanism and output slope depend on the type and flow rate of the materials. These devices are designed and manufactured in two types, fixed and portable. Hoppers have different shapes in terms of appearance, including the most commonly used types: Conical hopper Square hopper 🔸 Parabolic hopper (parabolic) Hopper with angled outlet 🔸 Hopper with one vertical side

The benefits of using Hopper

The industrial hopper is used to feed the materials in the determined amount to perform physical or chemical operations, as well as supply the input feed of the devices at a constant speed. If feeding materials and delivering feed to industrial machines is done by human power, it is not efficient. The work is not done uniformly and at the right speed. Therefore, industrial devices such as hoppers are used for proper feeding of production lines in factories.

What is the application of industrial hops in various industries?

1- Ready-made concrete production plants (to mix cement and sand with specific amounts): hoppers along with crushing devices such as various types of stone crushers, dryers, industrial sanders, mixers and conveyors for the sand and concrete production line Forms.

2- Rotary kilns for feeding the soil to the kiln: the input feed in the rotary kilns for lime baking must be uniform with a certain amount. If the input of materials is high, the calcination operation will be incomplete and the limestone will remain raw. And if the input is low, it will burn the lime. As a result, uniform feeding of input feed is essential.